24/7 Repair, Services And Maintenance

1/2 to 2 metric tonne capacities For contaminant controlled or corrosive environments.

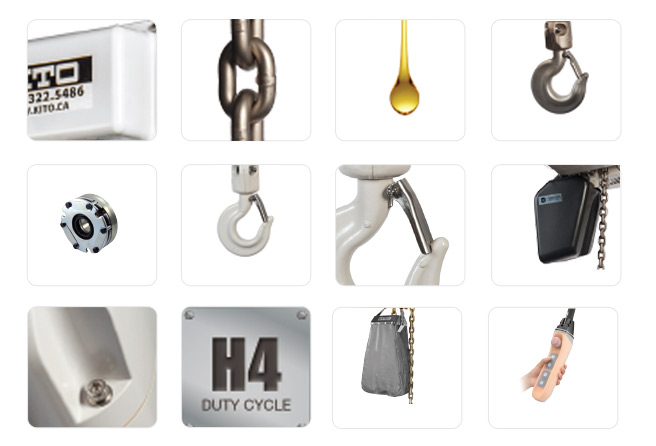

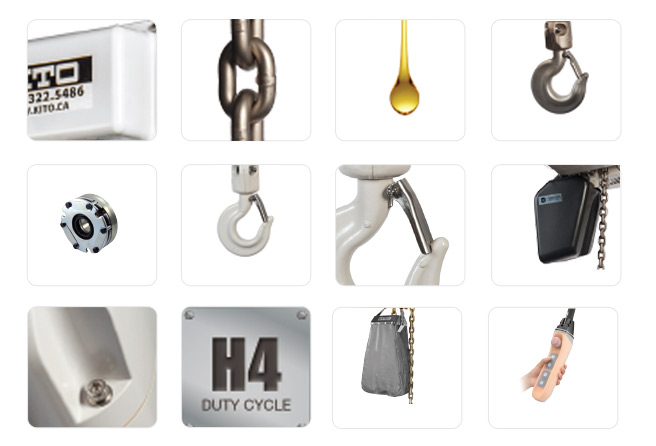

Kito’s Food Grade ER2 Electric Chain Hoist is well-suited for lifting applications in food, beverage, and pharmaceutical processing industries where pristine cleanliness is critical. Food grade lubricants used on the load chain and in the gearbox are NSF H1 compliant for safe use in any facility where incidental contact with product is a concern. The standard model also features white epoxy paint, stainless steel and nickel-plated hardware, and nickel-plated load chain making this hoist well-suited for contaminant controlled or corrosive processing environments.

In today’s fast-paced industrial landscape, businesses across Australia are constantly seeking ways to optimise their lifting operations and enhance productivity, especially in industries where cleanliness and hygiene are paramount. HES Cranes, a leading provider of customised lifting solutions in Melbourne and throughout Australia, is proud to offer the top-quality food grade chain hoist that is designed to streamline your lifting processes and improve overall efficiency in contaminant-controlled environments.

The food grade hoist is a state-of-the-art lifting solution that incorporates advanced features and materials to ensure pristine cleanliness and corrosion resistance. This hoist is engineered to handle lifting applications in food, beverage, and pharmaceutical processing industries where incidental contact with products is a concern. Some key features of the food grade chain hoist include:

The food grade chain hoist comes equipped with a range of standard features that ensure optimal performance, cleanliness, and safety in contaminant-controlled environments. These features include:

In addition to these specialized features, the food grade chain hoist also complies with a range of industry standards and certifications, including:

If you’re interested in learning more about how the food grade chain hoist can benefit your business, HES Cranes is here to help. Our experienced team is always ready to answer your questions and provide expert advice on the best food grade lifting solutions for your needs.

To discover how a high-performance food grade hoist can revolutionize your lifting operations in contaminant-controlled environments, contact HES Cranes today. Our friendly staff will be happy to discuss your requirements and provide you with a customised quote for a food grade lifting solution that meets your specific needs.

Don’t settle for less than the best when it comes to your lifting equipment in hygiene-sensitive industries. Choose HES Cranes for superior food grade chain hoist solutions that deliver unmatched performance, reliability, and cleanliness.

The food grade hoist is specifically designed for use in industries where cleanliness and hygiene are critical, such as food, beverage, and pharmaceutical processing. Its specialized features and materials make it well-suited for lifting applications in contaminant-controlled environments.

The food grade chain hoist is available in capacities ranging from 1/2 to 2 metric tonnes. This wide capacity range makes it suitable for a variety of lifting tasks in hygiene-sensitive industries.

Yes, all lubricants used in the food grade chain hoist, including the oils and greases for the load chain and gearbox, are NSF H1 compliant food grade lubricants. This means they are safe for use in facilities where incidental contact with food products may occur.

The food grade hoist features a combination of corrosion resistant materials, including white epoxy paint, stainless steel, and nickel-plated components. These materials provide excellent resistance to corrosion and contamination, ensuring the hoist remains in optimal condition even in challenging processing environments.

The food grade chain hoist complies with several important industry standards and certifications, including CSA Electrical Certification, ASME B30.16 Safety Standard, ASME HST-1 Performance Standard, and IP55 Environmental Protection. These certifications ensure that the hoist meets the highest standards of safety, performance, and environmental protection in food grade lifting applications.

Submit your enquiry using the form below, and we will get back to you as soon as possible.