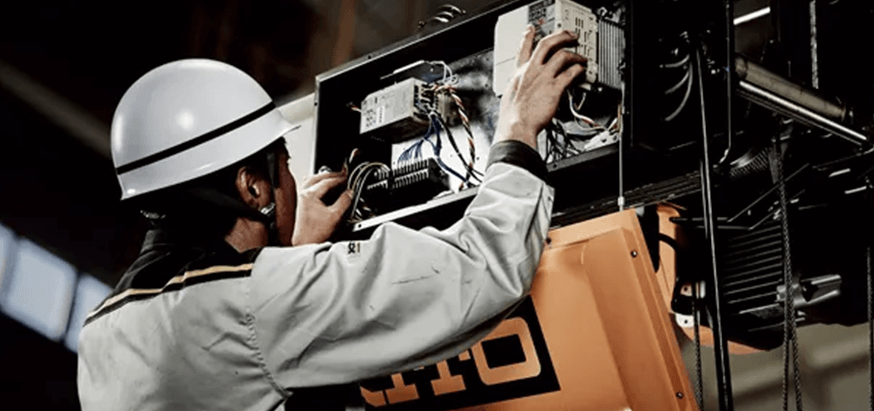

24/7 Repair, Services And Maintenance

OVERHEAD CRANE SERVICING MAINTENANCE INSPECTIONS:

Maintenance & Inspections – in accordance with AS2550.1 2011

Routine Planned Preventative Maintenance – in accordance with Equipment Manufacturers guidelines including Oil Analysis.

We offer 24 / 7 breakdown and consultation services to ensure your equipment is maintained to the highest level at all times.

Our commitment to service excellence means that we support you 100% and get it done right the first time, so that your uptime and equipment readiness meets your operational needs reducing the length of downtime subsequently reducing any loss of productivity.

Service Inspections and Preventive Maintenance will reduce your breakdowns and subsequent unscheduled interruptions of your business activities.

Based on each operation HES Cranes will review the best suitable package for your cranes and assets for our Total Maintenance Solutions based services.

HES Cranes will review in accordance with Original Equipment Manufacturer recommendations and/or Australian Standards by fixing your schedule intervals in accordance with asset class and use.

Typical activities during a service inspection include:

Detailed in depth crane component check.

Adjustment or re-adjustment of mechanical, electrical brakes, chains, clutch units and limit switches.

Consultation on measures to be initiated.

The ultimate goal for any business is to increase production uptime and performance by maximising productivity, improving safety while reducing production downtime and the total cost of maintenance. Having regular crane servicing.

AS2550.1-2011 Clause 7.3.4 states: